| |

|

|

|

Zeiss CMM |

|

|

|

Spectrum Analyzer |

|

|

|

X-RAY XG-1604T |

|

|

|

Mechanical Test

Machine |

|

|

|

Hardness Tester |

|

|

|

Surface Roughness

Tester |

|

|

|

| |

|

|

All our

subsidiaries have quality control systems consistent with

ISO/TS 16949 and ISO-9001 quality control systems. Our

quality control equipment includes ARUN MetalScan 2550

Spectrometer, Brown &Sharpe Global Status 7107 CMM, Zeiss

CMM, X-ray machines, tensile testing equipment,

automatic surface tester and more. Our well trained

technicians and quality control staff work three shifts to

guarantee that the quality of our parts exceeds the

requirements of our customers. |

|

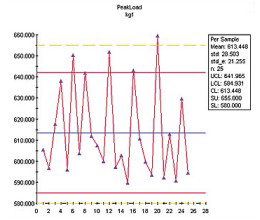

Our SQC Program |

|

Statistical

sampling and Statistical Process Control (SPC) techniques

are applied to all products in the manufacturing process.

The use of Statistical Quality Control (SQC) is part of our

overall quality control system and is part of our commitment

of continuous improvement in product quality. We work

closely with our customers to establish appropriate SPC and

SQC requirements. |

|

|

|

Coordinate Measuring Machine |

|

Our

customer's parts specifications are verified with our Zeiss

ACCURA 7/9/7 and Brown

& Sharpe GLOBAL STATUS 7107 coordinate measuring machine.

|

|

|

Zeiss ACCURA 7/9/7 |

STATUS 7107 |

|

Measuring range (in mm) |

700 x 900 x 700 |

700 x 1000 x 700 |

|

Volumetric Length measuring error MPEE |

1.6 + L/333 |

3.0 + L/250 |

|

Volumetric probing Error MPEP |

1.7 |

2.8 |

|

| |

|

|

|

ISO 9001:2008 |

|

|

|